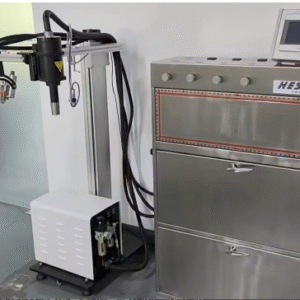

UV Laser Marking Machine Industry Applications:

Ultra-Fine Processing: Primarily used in the high-end market for ultra-fine processing, such as surface marking on packaging bottles for pharmaceuticals, cosmetics, cables, and other polymer materials. The result is exceptionally precise with clean, durable marks, superior to inkjet printing and free of contamination.

Flexible PCB Marking, Scribing: Used for marking and scribing on flexible PCB boards.

Micro-Hole and Blind-Hole Processing on Silicon Wafers: Ideal for creating micro-holes and blind holes on silicon wafers.

LCD Glass QR Code Marking: Marking QR codes on LCD glass.

Surface Hole Drilling on Glassware: Used to drill holes on glassware surfaces.

Metal Coating Marking: Marking on metal-coated surfaces.

Plastic Keys, Electronic Components, Gifts, Communication Equipment, Building Materials, etc.: Suitable for marking plastic keys, electronic parts, gifts, communication equipment, and building materials.

Key Advantages of UV Laser Marking Machines:

Ultra-Fine Marking: UV lasers have an extremely small focus spot size and a minimal heat-affected zone, enabling ultra-fine marking on special materials. This makes them the ideal choice for customers who require highly precise marking results.

Wide Material Compatibility: UV lasers are suitable for processing nearly all materials except copper, offering versatility in various applications.

Reviews

There are no reviews yet.