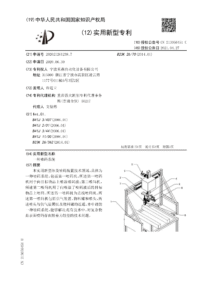

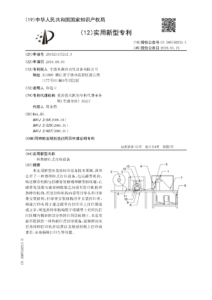

Fiber Static Laser Marking Machine

Integrated modular design with third-gen fiber laser (60% electro-optical efficiency, M²<1.4). Achieves <20μm focus spot and 4× faster marking vs. traditional machines. Fully air-cooled, maintenance-free for 8 years, 500W power consumption (saves ¥20k-30k/year).

Key Specs:

Beam Quality: Divergence angle 1/4 of semiconductor lasers

Compatibility: CorelDRAW/AutoCAD/Photoshop; PLT/PCX/DXF/BMP formats

Marking: Permanent RoHS-compliant engravings, automatic serial/batch codes, barcodes/QR codes

Design: Compact, harsh-environment resistant

Applications: High-precision part labeling, barcoding, surface engraving.